Perform Real-Time Statistical Process Control

Manufacturing Software Solution

Statistical Process Control

Real-time Quality Control Software

WinSPC is real-time statistical process control software used by quality teams to improve product quality, reduce process variation, and optimize manufacturing processes.

WinSPC collects process data from the shop floor and transforms it into real-time, actionable quality information for operators, quality personnel, manufacturing engineers and management.

Improve product quality

Increase customer satisfaction

Reduce scrap, waste & rework

Optimize processes & yield

Achieve regulatory compliance

Capture

Collect shop-floor data in real-time from virtually any source—gages, devices, machines, and other data sources. WinSPC’s simple, three-step connection process makes it easy to simply connect and begin collecting data from almost anything.

- Connect and collect data from any RS232 serial or USB device

- Capture data from text files, .csv files, Microsoft Excel, any ODBC-compliant database, or machines such as CMMs or PLCs

- Integrate with other manufacturing systems using OPC, OLE, and DDE—WinSPC’s built-in APIs supports over 500 OLE methods and properties

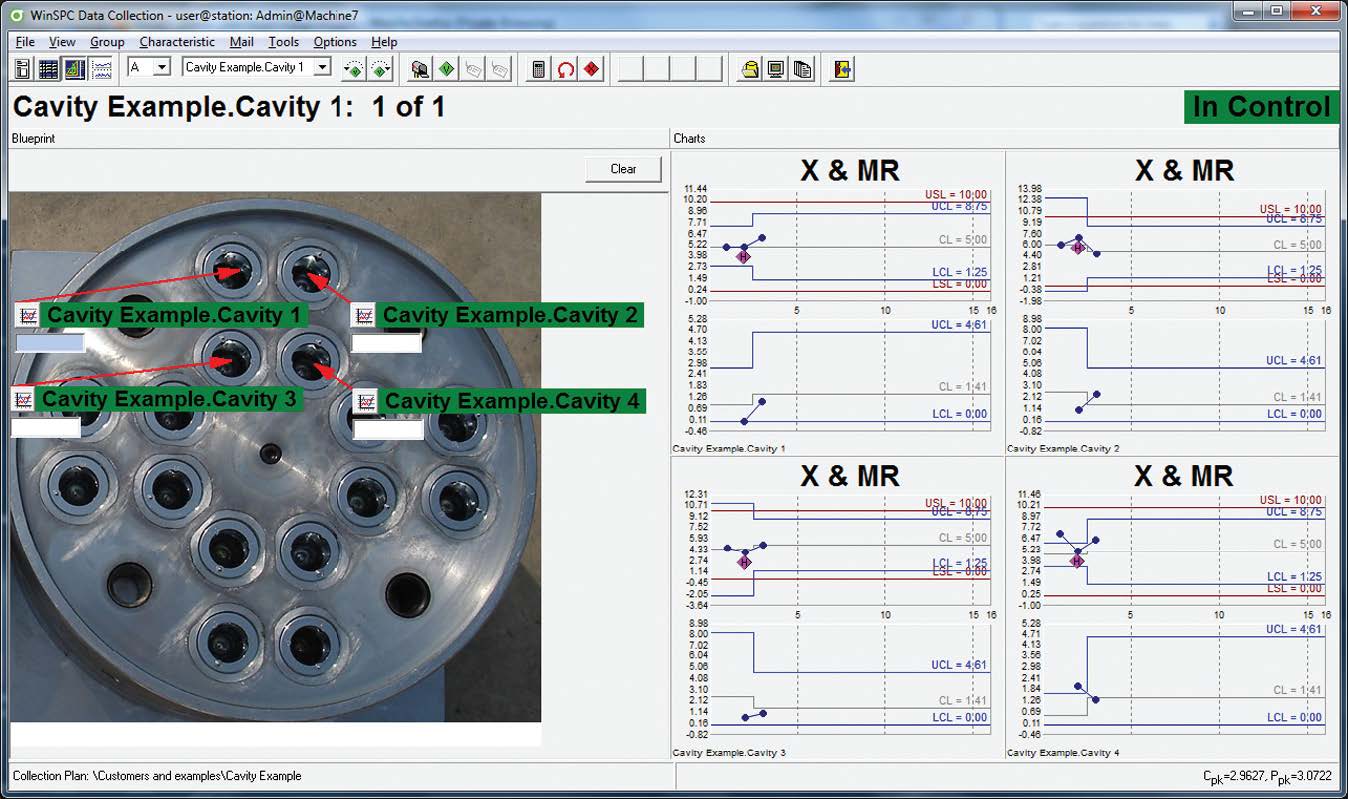

Monitor

Empower your operators with real-time, actionable intelligence. WinSPC displays real-time control charts on the shop floor—enabling your team to immediately detect and correct process issues.

- Display a variety of control charts and SPC charts

- Customize screen layouts

- Scroll to view data from the “beginning of time”

- Save time using built-in support for standard SPC rules

- Click to drill-down and perform statistical analysis

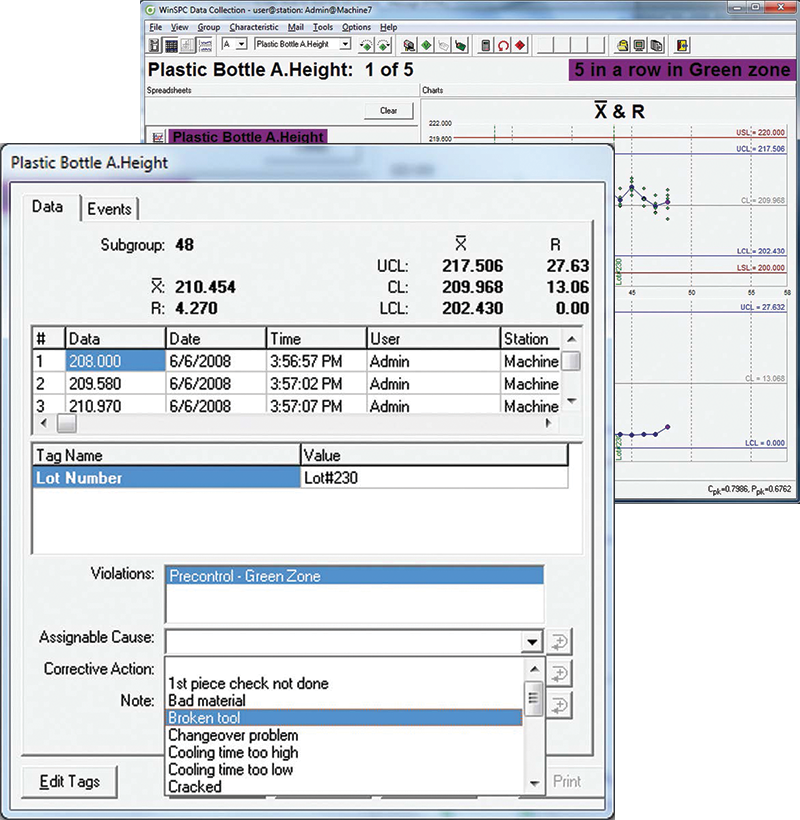

Alert

Automatically alert personnel, execute custom programs, shut down machines, or engage other systems if a nonconformance or rule violation occurs using WinSPC’s built-in triggers. Whether your requirements are as simple as sending an email or as complex as triggering a process within a corrective action system, WinSPC gives you the power to close the quality loop from “detection-to-correction.”

- Use a simple pull-down menu to schedule a variety of different notifications and alarms for nearly any condition

- Program your own custom triggers to schedule enterprise-wide alarms or communicate bidirectionally with other systems or machines or send a command to a device

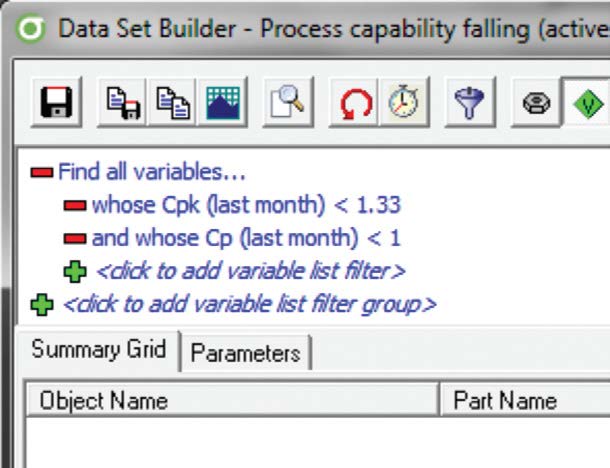

Expose

Answer questions, detect changes and discover trends with WinSPC’s data sets. Using data sets quality teams can identify, prevent, and prioritize quality issues at a macro level. Unlike the traditional microscopic nature of SPC, which focuses on a specific variable, data sets offer a broad view of your database—enabling you to proactively monitor and uncover high priority issues.

- Scan, query, and filter large amounts of data

- Maintain a watchful eye over multiple processes

- Expose areas in need of improvement

- Reveal potential issues before they become problems

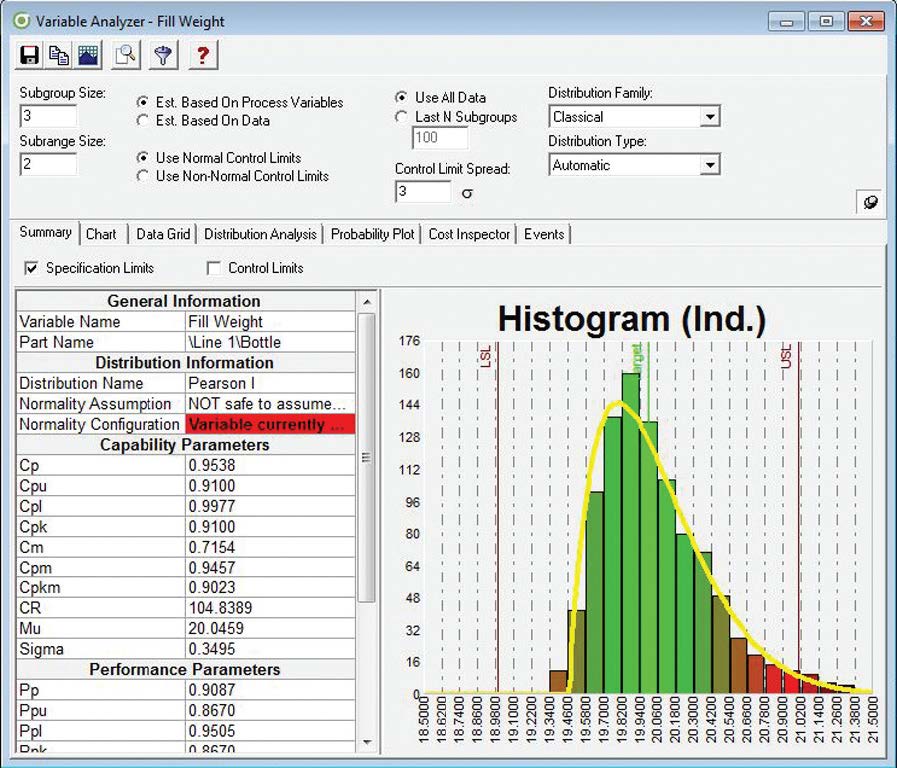

Analyze

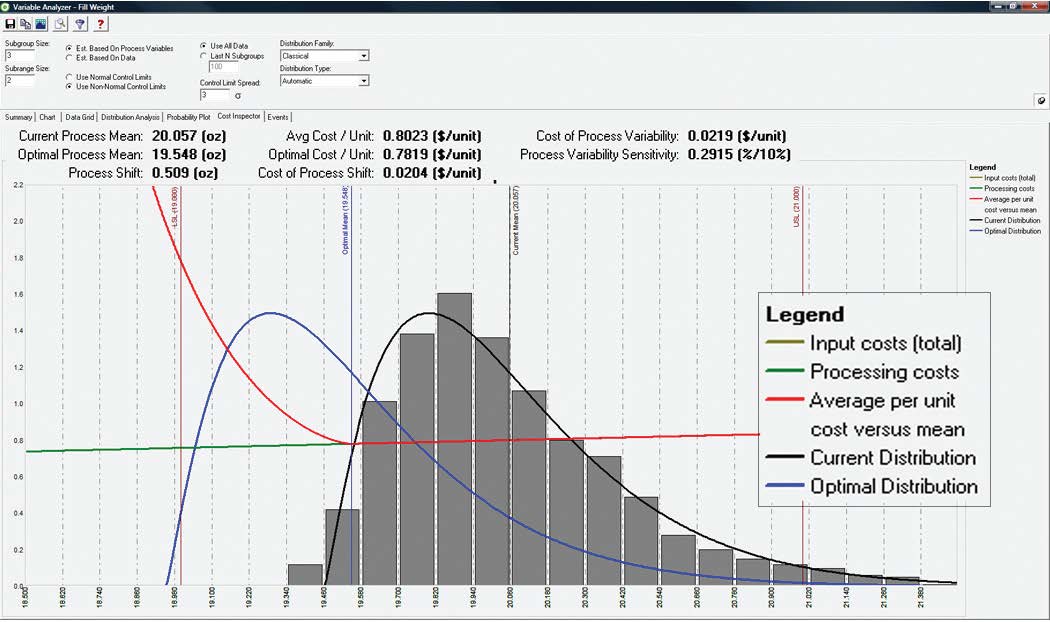

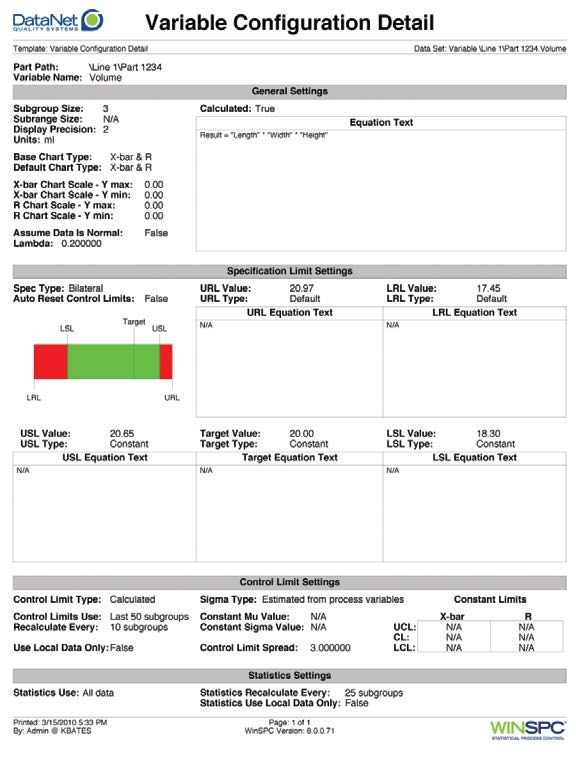

Experiment, visualize, and reveal more information about any variable using the one-click variable analyzer. The variable analyzer delivers both point-of-production and historical analysis capabilities. It puts an entire set of statistical tools at your fingertips—giving you a comprehensive view of your data from one convenient screen.

- Drill down for detailed views

- Sort, group, and filter data to reveal issues and draw conclusions

- Slice and dice data and perform “what-if” analysis

- Manipulate the options that affect your statistical calculations like subgroup size, data range, distribution type, and more

- Review all events logged for a particular variable

- Copy/paste or export data to other popular formats

Justify

Identify the hidden cost of give-away, overfill, rework or scrap that weaken a company’s profits using WinSPC’s Cost Inspector™. The Cost Inspector links manufacturing cost information with current and historical process data, empowering quality teams to:

- Search process data across all operations to uncover costly process problems

- Identify sources of give-away, overfill, scrap or waste

- Calculate potential savings per unit by reducing process variation or shifting processes to optimal mean

- Translate process improvement statistics into dollars saved for the company

- Produce cost-based reports to show executive management the return on investments in quality

Report

Quickly create, publish and share quality reports across your organization using WinSPC’s graphical report builder and dozens of standard report templates.

- Build hundreds of custom reports using a visual interface— no programming skills required

- Publish to PDF or HTML and email in a single click

- Leverage a library of commonly used report templates

- Configure your own library of commonly run reports

- Link reports to data sets to quickly right-click and produce reports

- Automate daily, weekly, or monthly reporting tasks with WinSPC and Microsoft Task Scheduler

Comply With Regulatory Requirements

WinSPC’s event log feature enables manufacturers who are subject to regulatory requirements (FDA, USDA, ISO, TS, etc.) to build auditability into their manufacturing process.

- Support FDA 21 CFR part 11 requirements for electronic signatures and forced log outs for system security

- Capture, trace and securely store process data for auditability

- Record every system event, including the deletion of event log items, electronic signatures, and system configuration changes

- Quickly filter and retrieve nearly all system activities such as startup/shutdown, security, administration, data collection and violations

Exchange Information With Systems & Software

Integrate WinSPC with other software and hardware using our built-in APS’s with over 400 methods and properties of OLE . WinSPC also communicates bidirectionally with other systems, software and devices via OPC (Version 1, 2, and 3), DDE, serial, and ODBC.

- Built-in APIs

- Over 400 methods and properties of OLE

- Bi-directionally communicate with intelligent machines and devices

- Successfully integrate with other MES, ERP, HMI systems